Cómo un contratista general de Alabama se asoció con líderes del sector tecnológico para automatizar la documentación visual de 360 grados

13 de octubre de 2020

Un contratista general de Alabama, una empresa de robótica de Boston y un desarrollador de software para drones de San Francisco pueden parecer socios poco probables. Sin embargo, la reciente colaboración entre Brasfield & Gorrie, Boston Dynamics y DroneDeploy abarcó ambas costas y el sur profundo y dio lugar a un gran avance tecnológico en el sector de la construcción.

La historia

En Brasfield & Gorrie llevamos años deseando implantar la robótica terrestre móvil en la construcción. Vimos el potencial de estos robots para capturar datos y liberar a los empleados para que se centraran en actividades más complejas. Pero los sistemas basados en ruedas y orugas carecían de la flexibilidad necesaria para un entorno de construcción complejo y cambiante. Reconocimos el ágil robot móvil Spot de Boston Dynamics como la primera plataforma robótica potencialmente viable para un entorno de construcción. Al ver el potencial para automatizar la captura de datos en nuestros sitios de trabajo, solicitamos participar en el Programa de Adopción Temprana de Spot de Boston Dynamics en septiembre de 2019.

El concurso de robótica allana el camino

Nuestra candidatura a este programa exclusivo se vio reforzada por una reciente competición de robótica interna que demostró nuestro compromiso con la innovación. A principios de 2019, los equipos de Virtual Design + Construction de todas nuestras oficinas se enfrentaron al reto de programar un DJI RoboMaster para que siguiera una ruta repetible por la oficina, se detuviera en lugares predeterminados para capturar fotos de 360 grados y las subiera a una plataforma de gestión de datos de construcción basada en la nube. Los equipos no podían hacer nada que anulara la garantía del robot, lo que supuso un reto; el RoboMaster solo está equipado con una cámara de baja resolución y un láser, no con una cámara de 360 grados. Además, en aquel momento, el RoboMaster utilizaba un sistema de programación gráfico basado en bloques de arrastrar y soltar con una funcionalidad limitada, en lugar del típico código basado en texto. El coordinador del VDC, Grayson Savage, que formaba parte del equipo ganador, se inspiró en la fibra óptica y utilizó el láser para avisar a un pequeño ordenador cuando llegaba el momento de hacer una foto.

Las relaciones crean la receta para la innovación

Cuando nos enteramos de que DroneDeploy, nuestro socio desde hacía tiempo, también se había inscrito en el programa Boston Dynamics Early Adopter, nos pareció lógico asociarnos para esta iniciativa. Brasfield & Gorrie se centraría en construir el hardware adecuado y automatizar la recogida y captura, mientras que DroneDeploy se encargaría de la carga, el procesamiento, el alojamiento y la interacción de los datos.

Enfoque

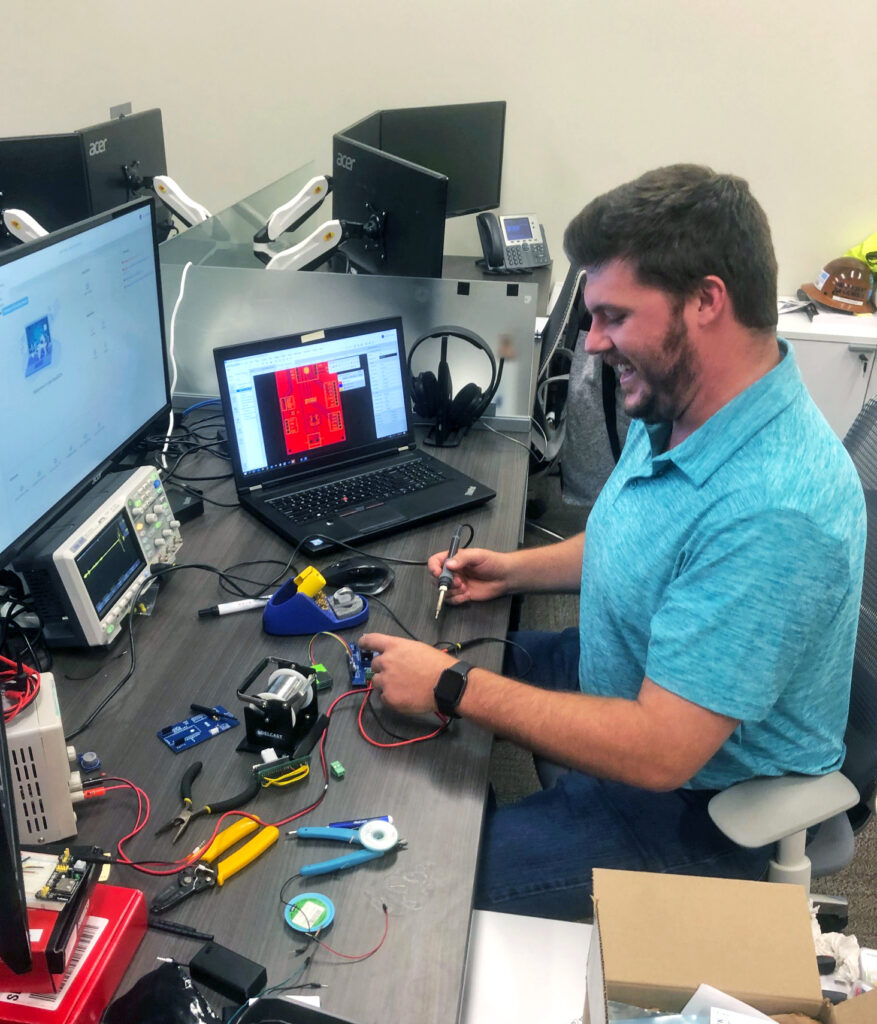

Al igual que en nuestro desafío RoboMaster, nos encontramos con limitaciones en cuanto a los sistemas de Boston Dynamics a los que podíamos acceder y a los que no, y tuvimos que pensar de forma creativa para desarrollar soluciones. Utilizamos el kit de desarrollo de software Spot de Boston Dynamics para interactuar con el robot y darle instrucciones sobre por dónde caminar y cuándo empezar y parar. Luego desarrollamos nuestras propias cargas útiles, o hardware externo, que se instalan a bordo del robot para dar órdenes a la cámara y cargar los datos. "Me encanta trabajar en el espacio donde se encuentran el hardware y el software, diseñando placas de circuitos y programando microcontroladores para hacer que sucedan cosas físicas en el mundo real", dice Grayson.

En colaboración con DroneDeploy, los miembros del equipo de Brasfield & Gorrie avanzaron rápidamente en varios frentes, como la creación de una placa de distribución de energía para las cámaras y ordenadores de a bordo y una aplicación de misión basada en web para dar órdenes a Spot. Al compartir la energía de la batería de Spot, podíamos estar seguros de que las cargas útiles no morirían mientras Spot siguiera funcionando. Esto sería esencial si Spot tuviera que funcionar de forma autónoma durante la noche, recopilando datos y tomando fotos del progreso. El equipo de Brasfield & Gorrie también desarrolló una placa de sensores ambientales que se conecta a la placa de potencia y registra gases peligrosos, partículas, sílice, niveles sonoros peligrosos y temperaturas y humedad extremas en los lugares de trabajo. Esto podría integrarse en el mapa de DroneDeploy como una capa de datos adicional que proporcionaría notificaciones de seguridad críticas.

"Cuando buscábamos socios pioneros que desarrollaran flujos de trabajo para desplegar Spot sobre el terreno, Brasfield & Gorrie fue una elección obvia", afirma Brian Ringley, Director de Tecnología de la Construcción de Boston Dynamics. Reunieron al equipo de innovación ideal, que incluía miembros que comprendían tanto los retos de la supervisión de obras de construcción como las oportunidades latentes para la automatización de procesos, y tenían los conjuntos de habilidades técnicas complementarias en el desarrollo de hardware y software para garantizar que pudieran aprovechar al máximo el SDK de Spot para ampliar las capacidades del robot en entornos dinámicos". Brasfield & Gorrie entiende realmente cómo maximizar el valor empresarial de las tecnologías de construcción emergentes."

El avance

Esta colaboración entre Brasfield & Gorrie, DroneDeploy y Boston Dynamics dio lugar a una forma única de utilizar Spot con el nuevo flujo de trabajo DroneDeploy 360 Walkthrough, una solución integral de documentación de la construcción. Spot captura y carga de forma autónoma grandes cantidades de datos con mayor frecuencia y repetibilidad en comparación con los métodos tradicionales, y DroneDeploy ayuda a dar sentido a los datos.

DroneDeploy 360 Walkthrough es más eficiente, rentable y seguro, y libera a los ingenieros de proyectos para que se centren en las tareas que requieren su experiencia. Brasfield & Gorrie ya utiliza fotografías de 360 grados, capturadas por los empleados, para la documentación e inspección de proyectos, y vemos la automatización robótica como la evolución obvia del actual proceso, que requiere mucho tiempo.

La pasión de Grayson Savage por la robótica se remonta a su juventud, cuando gastó el primer sueldo de su trabajo en el instituto en un kit de desarrollo de microcontroladores. Mientras estudiaba ingeniería aeroespacial en la universidad, Grayson hizo prácticas en Brasfield & Gorrie. Llamó la atención del grupo VDC cuando escribió un software para automatizar la laboriosa tarea de organizar y actualizar las solicitudes de información de un gran proyecto hospitalario. Su programa procesaba 100 RFI en unos cinco minutos. Grayson se unió al equipo de VDC de la empresa en 2015 y pronto dirigió la investigación y el desarrollo de un robot para ayudar a automatizar los procesos de diseño de MEP y paneles de yeso. Presentó esta investigación en la conferencia de 2016 de la Sociedad Internacional de Automatización y Robótica en la Construcción. La pasión y la experiencia de Grayson en robótica siguen haciendo avanzar nuestros esfuerzos de innovación.